Metal Roof Flashing: Why is it Important?

January 23, 2021

Posted in: Building Maintenance, Metal Building Insulation, Metal Building Tips, Metal Buildings, Metal Roof Flashing

January 23, 2021

Posted in: Building Maintenance, Metal Building Insulation, Metal Building Tips, Metal Buildings, Metal Roof Flashing

When you own a metal building, it is vital that you work hard to prevent leaks and ensure that your building is watertight. To do this, you will need to utilize quality underlay when lining the area and install roof flashing. This will prevent the water from being able to enter any gaps, vents, or openings. Take a moment to find out more about the different types of roof flashing and how to use them effectively in your steel building.

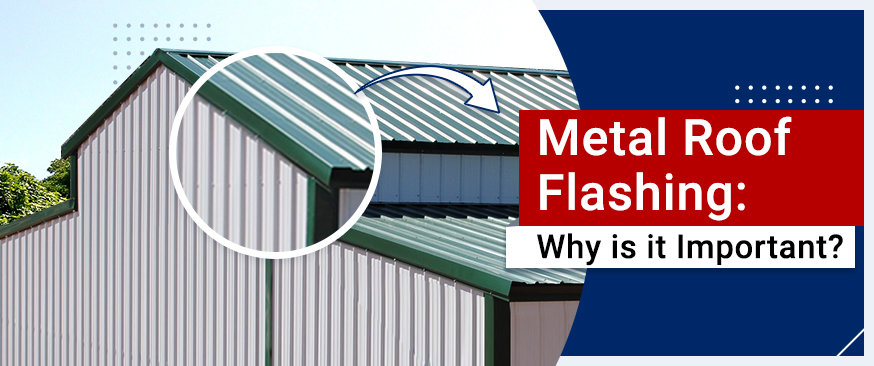

What Do We Mean by Metal Building Roof Flashing?

Roof flashing is the material that is used to seal your roof from the elements, such as extreme weather conditions. Traditionally it is made from metal, and it provides water with a way to run off your building without penetrating it. It can be used to seal the roof and any vents, gaps, windows, or other openings. This will create a seal that will keep your prefab building from experiencing leaks.

When flashing is installed, it is usually placed one piece on top of another as you see with roof shingles, or it can also be installed as one sealed area depending on the type of area you need to protect. Some roof flashing companies sell cheap options that are not made from metal, but you will find that they disintegrate quickly and will need replacing annually in order to keep your building sealed.

Choosing metal flashing gives you long-lasting protection and peace of mind. You can enjoy an energy-efficient metal building without having to worry about replacing it for many years.

Is Roof Flashing Really That Important?

Many of our clients ask us whether metal building roof flashing is an area in which they can save money but sadly, it is not. Roof flashing is vital to keeping your building sealed and secure. This ensures that it does not experience on-going water damage that will compromise the integrity of the steel building itself. Because flashing is used to seal any areas that are exposed to the elements (mild or moderate or extreme weather conditions), it is essential that you use it in any building project you are undertaking.

The other important aspect of installing roof flashing is that it reduces air movement and prevents drafts from circulating. If you are spending money on energy bills for a structure that is not correctly sealed, then you will find that you end up paying more than you need and owning a building that is not environmentally friendly.

The Different Types of Roof Flashing and How to Install Them

Not all metal buildings are created the same, and different areas of exposure will need different types of roof flashing for them to work effectively. Take a look at the different types below before you choose the right type for your building:

- Rake Trim – this type of flashing is used at the roofline of the building, specifically where the roofline meets the gable. When you install this type of flashing, you will need to cut and angle it so that it can be folded into the side of the roof to produce a seal. Before you install the flashing to the roof, you will need to take the underside of the flashing and apply butyl tape to it. This will give you a seal that will fend off moisture. When it is ready to be installed, and the tape has been applied, you will need to use fasteners and space them from 12 – 24 inches apart.

- Eave Trim – this type of flashing is used to help stop water from entering the roof fascia and works to redirect water to the ground rather than letting it penetrate the building. With eave trim, you will need to install underlayment first and then install the metal flashing on the top. Doing this will stop moisture from penetrating the building. Simply cut the flashing to the right size and then screw it into the roof with your screws spaced 12 – 24 inches apart.

- High Side Peak Trim – this type of flashing is used at the highest point of the roof and works to stop moisture from getting in between the sloping panels. When you are preparing to install this flashing, you will need to apply butyl tape to the top edge of each panel, with the outside closure placed on the top of the tape. Once you have done this, you will need to apply a layer of sealant on the closure. After your preparation is completed, you will have to cut and angle it to fit the closure space as well as the rake trim, this is an essential part as any gaps will leave the building weak to leaks. Once all your flashing has been put in place, you will need to fasten them in at each major rib.

If you aren’t sure which type will work the best for your metal building, then do not worry, we are here to help. Our knowledgeable team will happily provide you with personalized advice so that you can make the right purchase for your steel building.

Let Us Help With Your Metal Roof Flashing

When you are looking for expert help and support, then Get Carports is the best choice for any American consumer. It’s clear that installing the right metal roof flashing is vital to the upkeep of your building and will save you from unexpected leaks or damage that may occur otherwise. When you buy your metal building from us, we will work with you to ensure that the specifications of the building and the metal flashing is appropriate to your needs.

Buying from Get Carports gives you access to a company that puts customers first and provides best-guaranteed prices across the country. We provide expert information and advice on metal buildings and pride ourselves on ensuring on-time delivery and quality installation. What are you waiting for? Call us today at (800) 691-5221 to get your metal building ordered.